Technical Specifications

| Parameter | Specification/Feature | Test Standard |

|---|---|---|

| Base Material | 450gsm matte black cardstock + water-based matte coating | ISO 536 |

| Surface Finish | High-precision UV polishing (85°±5 gloss level) | ASTM D523 |

| Load Capacity | Static load-bearing ≥12kg / Dynamic handle test ≥500 cycles (no breakage) | GB/T 1040 |

| Printing Process | Heidelberg 6-color printing + laser-etched logo (min. line width 0.2mm) | Pantone GRACoL |

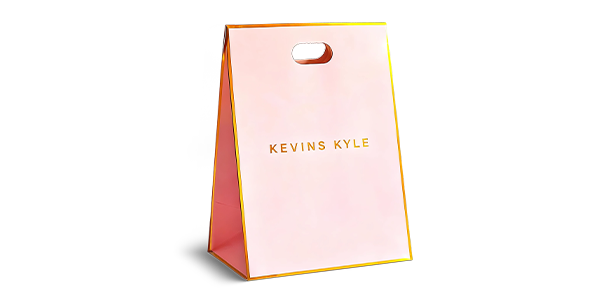

| Handle Design | 25mm cotton-linen woven strap (tensile strength ≥200N) + concealed rivet fixation | EN 14972 |

| Size Options | Small (30×25×10cm) / Medium (40×30×12cm) / Large (50×35×15cm) (±2mm tolerance for custom sizes) | ISTA 3A |

| Eco-Certification | FSC Mix Certified / EU REACH SVHC 211 non-detected | SGS Test Report |

| Special Features | Anti-fingerprint coating / Optional RFID anti-theft chip slot | ISO/IEC 14443 |

Advantages Over Conventional Matte Black Bags

| Traditional Matte Black Bags | Our Upgraded Version |

|---|---|

| Standard black cardstock + matte film | Custom black-core paper (L* value ≤8) + nano-matte coating (silky touch) |

| Screen printing (prone to fading) | UV-cured printing (4H abrasion resistance) + laser-positioned foil stamping (±0.3mm precision) |

| Glued handles | Ultrasonic welding + mechanical rivets (60% higher load capacity) |

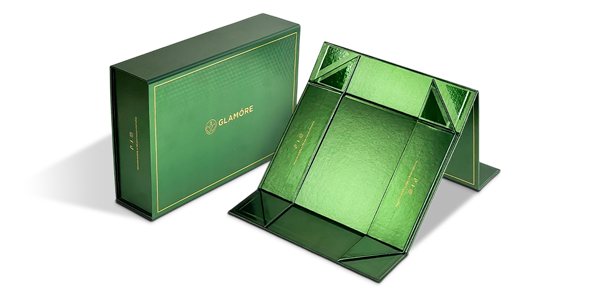

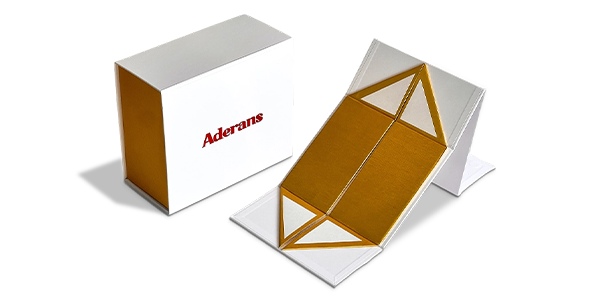

| Fixed sizes | Smart die-cutting system (1-minute mold switching for different sizes) |

Recommended Applications

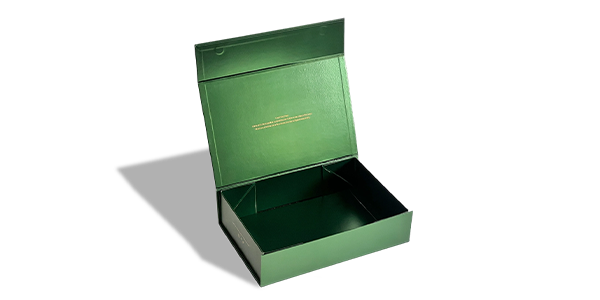

- Luxury Retail Stores: Magnetic closure + dust-proof inner bag

- Fashion Week Gifts: Embedded NFC chips linking to runway videos

- VIP Exclusive: Thermochromic ink displaying membership tier (body-temperature activated)

Customization Process

- Requirement Confirmation (Free 3-tier blackness samples)

- Structural Design (3D renderings in 48 hours)

- Functional Testing (Includes abrasion/humidity/load tests)

- Mass Production (10-day lead time, MOQ 5,000 units)