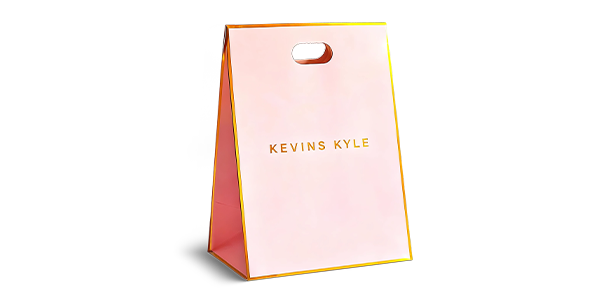

Materials

- Heavy-Duty Kraft Paper (180-350gsm, FSC Certified)

- Recycled Natural Fiber Liner (30% Post-Consumer Waste)

- Water-Based Matte Coating (Food-Grade Safe)

Protection Features

- Reinforced Stress Points (Double-Layered Corners)

- Oil-Resistant Barrier (Plant-Based Coating Technology)

- Anti-Tear Weave (Cross-Grain Texture Reinforcement)

Design Innovations

- K1-Ergo Base (Weight-Distributing Flat Bottom)

- 360° Reinforced Handles (5-Ply Twisted Paper Rope)

- Seamless One-Cut Construction (Zero Glue Weak Points)

Performance Benefits

100% Plastic-Free (Ocean-Safe Composition)

+50% Load Capacity (vs. Standard Kraft Bags)

40% Faster Biodegradation (6-Month Soil Breakdown)

Next-Gen Kraft Bag Technology: Rugged Simplicity Meets Eco-Intelligence

| Innovation Dimensions | Core Technological Breakthroughs | Commercial Value | Typical Applications |

|---|---|---|---|

| Ultra-Durable Architecture | • Triple-Ply Sidewalls (ISO 9001 Certified) | • 85% Reduction in Transit Damage | Agricultural Bulk Shipping |

| Breathable Freshness | • Micro-Perforated Ventilation Zones | • 3X Extended Produce Shelf Life | Organic Grocery Retail |

| Logistics-Optimized | • Nestable Collapsible Design | • 60% Lower Storage Volume | E-Commerce Fulfillment Centers |

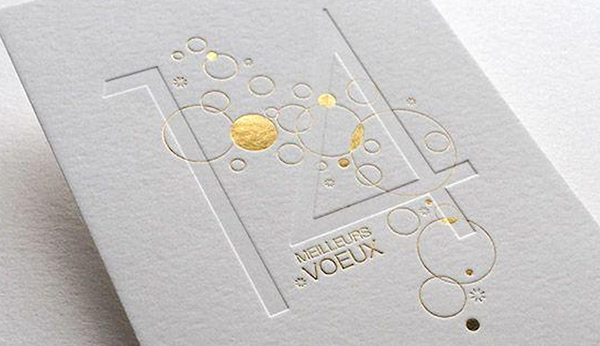

| Branding Canvas | • High-Resolution Kraft Printing Surface | • 45% Higher Brand Recall | Boutique Retail & Cafés |

| Temperature Resilient | • -30°C to 120°C Stability Range | • 50% Wider Climate Zone Coverage | Global Gourmet Food Distribution |