In the gift box packaging customization industry, specialty paper is highly sought after for its unique textures, tactile feel, and premium appearance. However, many clients might not realize that manufacturers often approach specialty paper orders with extra caution. Why is printing on specialty paper so challenging? As a professional gift box packaging customization company, we delve into this issue in this article, offering practical insights to help you make informed decisions.

First, let’s discuss the structure of specialty paper. Standard packaging paper typically uses a “1+1+1” or “1+1” structure—for instance, a cardboard core sandwiched between layers of lining paper to enhance durability and flatness. This design is like a multilayer sandwich, ensuring the substrate remains stable.

But what about specialty paper? To cut costs, some suppliers simplify the structure by using a single thick paperboard (a “1” structure) without additional lining layers. This might seem economical, but it hides risks. Imagine the paperboard itself acting as the substrate; during printing and drying, ink can penetrate the paper fibers. Over time, or in storage environments, the board may warp due to moisture changes or even develop cracks. This is why many manufacturers avoid single-structure specialty paper in items like hang tags—what saves a little money upfront might lead to greater losses from defective products.

Suppose you custom-ordered a batch of high-end gift boxes using specialty paper. Weeks later, during a warehouse check, you notice fine cracks on the surface and uneven ink colors. This not only affects aesthetics but could also result in customer complaints—a classic outcome of structural issues!

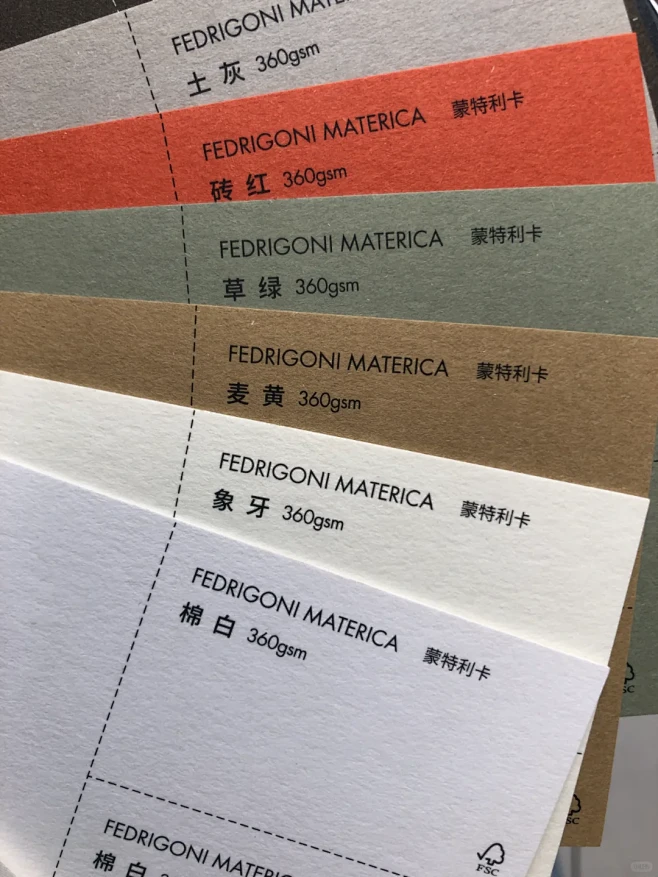

Printing processes fundamentally rely on the surface characteristics of the substrate. Most standard papers have smooth surfaces that allow ink to dry quickly and adhere evenly, forming a consistent coat. However, specialty paper often features irregular textures—such as embossing, roughness, or uneven surfaces. It’s like driving on a bumpy road; ink tends to flow along these textures during the critical few seconds when it’s not fully dry, leading to blurred edges, color inconsistencies, or loss of detail.

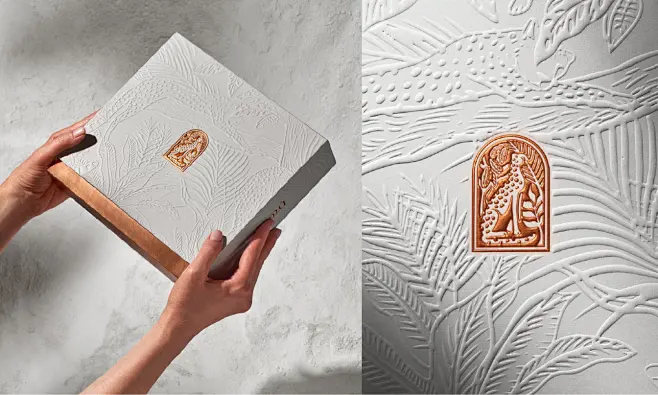

For example, if printing a fine logo or text, even minor flow can cause fatal errors, rendering the entire product useless. This not only increases production costs but also delays delivery times. Thus, when dealing with specialty paper, manufacturers must adjust printing parameters, use specialized inks, or conduct multiple tests, all of which add to the complexity and risk.

Have you ever wondered why high-end brands still insist on using specialty paper? The answer lies in balancing texture with brand identity. With technical support from experienced manufacturers, specialty paper can elevate your product’s appeal—but only if you choose the right partner.

Q: Why is specialty paper more prone to cracking?

A: It primarily stems from simplified structures. Single-layer specialty paper lacks support layers, causing uneven internal stress due to ink penetration and environmental factors like humidity, which leads to warping or cracking. We recommend using composite structures, such as adding lining paper, to improve stability.

Q: How can I reduce the risk of printing failures on specialty paper?

A: First, select a capable manufacturer with advanced equipment and an experienced team. Second, conduct sample tests in advance to simulate storage conditions. Finally, consider hybrid materials that balance cost and quality.

Q: Is specialty paper suitable for all types of gift boxes?

A: Not necessarily. For simple designs or large-volume orders, standard paper might be more economical and reliable. But if you’re aiming for a unique tactile experience, specialty paper is worth trying—just ensure your manufacturer can handle its complexities.

| Feature | Standard Paper | Specialty Paper |

|---|---|---|

| Structure | Typically multi-layer composite (e.g., 1+1+1) | May be single-layer thick board |

| Printing Surface | Smooth, easy for ink adhesion | Irregular textures, prone to ink flow |

| Risks | Low, even drying | High, potential for warping and cracking |

| Cost | Lower, suitable for large volumes | Higher, requires additional testing and handling |

| Ideal Use Cases | Standard gift boxes, tags | High-end custom, limited edition products |

While printing on specialty paper presents challenges, partnering with a professional manufacturer can elevate your gift boxes to new heights. Our company has years of experience in gift box packaging customization, equipped with advanced technology and a dedicated team to provide reliable solutions. If you’re planning a specialty paper project, contact us—we’ll help you mitigate risks and create stunning packaging!

Through this article, we aim to enhance your understanding of specialty paper printing. Remember, choosing a capable manufacturer is key—don’t let minor paper issues ruin your exquisite designs!

As festivals approach, many brands look for suitable gi […]

When businesses seek packaging solutions—whether for gi […]

With the rapid development of the internet, businesses […]

In 2026, China’s packaging manufacturing industry conti […]