Many customers see the term “grey board” and immediately think of “cheap and easy to deform”, which is actually a stereotype of low-grade grey board. In the material warehouse of a colorful hardcover box factory, grey board can be divided into three grades according to quality, and the performance and application scenarios of different grades vary greatly:

| Grey Board Grade | Density (g/cm³) | Hardness (Stiffness Value) | Application Scenarios | Price Range (vs. White Cardboard) |

|---|---|---|---|---|

| Ordinary Grey Board | 0.6-0.8 | 100-150g·cm | Low-end gift boxes, storage box liners | About 1/3 of white cardboard |

| Mid-Grade Grey Board | 0.8-1.0 | 150-200g·cm | Mid-range gift boxes, food packaging boxes | About 1/2 of white cardboard |

| High-End Grey Board | 1.0-1.2 | 200-250g·cm | High-end watch boxes, necklace boxes, luxury gift boxes | About 2/3 of white cardboard |

It is obvious from the table that the density and hardness (stiffness value) of high-end grey board are already close to those of traditional high-end inner materials such as grey-backed white board and white cardboard (the stiffness value of white cardboard is about 220-280g·cm), but the price is still about 1/3 lower than that of white cardboard. This is why more and more colorful hardcover box factories have recommended high-end grey board to customers pursuing “quality + cost-effectiveness” in recent years.

By optimizing the raw material ratio and pressing process, high-end grey board solves the problem of “softness and brittleness” of ordinary grey board. We has conducted tests: a watch box made of high-end grey board showed no obvious deformation after 50 opening and closing tests; while the same type of box made of ordinary grey board had edge collapse after 20 opening and closing tests — this means that high-end grey board can fully meet the durability requirements of high-end gift boxes, while the cost is lower than that of white cardboard, helping customers control the budget.

Many customers will worry: “Using grey board to make high-end gift boxes, will it increase the processing difficulty? Such as hot stamping falling off, paper lamination bubbling?” In fact, on the contrary, high-end grey board has stronger processing adaptability:

Nowadays, many high-end brands require “environmentally friendly materials” when customizing gift boxes. High-end grey board is mostly made of mixed recycled pulp and virgin pulp, which meets the EU ROHS environmental protection standard, and the recyclable utilization rate reaches 95%, which is more favored by environmentally friendly brands than some non-degradable synthetic materials.

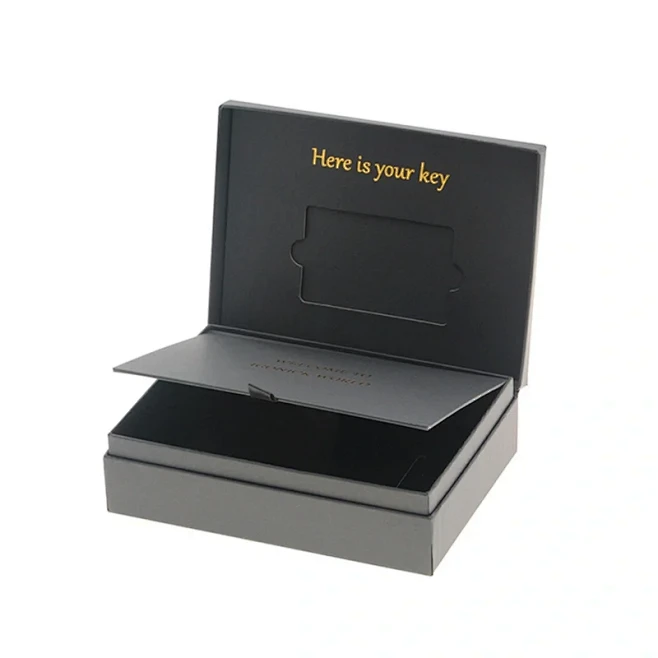

A1: Not at all. When a colorful hardcover box factory makes a gift box, it will laminate coated paper, specialty paper or film on the surface of the grey board. The final appearance seen by customers is the color and texture of the outer paper, and the grey board only serves as a “supporting framework” and will not expose the base color. We once customized a necklace box for a jewelry brand, using high-end grey board as the inner framework and laminating gold-stamped specialty paper on the outer layer. The appearance of the finished product was no different from that of the gift box made of white cardboard, and the customer feedback was “can’t tell it’s made of grey board at all”.

A2: No. Our factory has regular thickness (1.5mm-5mm) inventory of high-end grey board. If customers need special thickness (such as 6mm or more), the customization cycle only takes 3-5 days, which is basically the same as the delivery cycle of ordinary grey board and will not affect the production progress of the overall gift box.

As a manufacturer with 10 years of experience in custom gift box packaging, Foshan Shengcai Paper Packaging recommends high-end grey board, mainly to “help customers balance quality and cost”. Many customers want to make high-end gift boxes but do not want to bear the high cost of white cardboard; or want to make lightweight gift boxes but worry that ordinary grey board is not durable — high-end grey board just solves these two pain points.

For example, last year we customized a series of gift boxes for a watch brand. The customer originally planned to use white cardboard with a high budget; after we recommended high-end grey board, we helped the customer reduce the material cost by 25% while ensuring the hardness and stiffness of the box body remained unchanged. Finally, the finished product also passed the brand’s drop test (no damage after 1.2-meter drop), and the customer added another 3,000 sets of orders later.

We hope that through this content, you can reunderstand grey board: it is not a synonym for “low-end material”. With the advantages of “performance close to high-end cardboard, lower cost, and easy processing”, high-end grey board has become the “cost-effective ace” of colorful hardcover box factories. If you are customizing gift boxes and struggling with the selection of inner materials, feel free to contact us, Foshan Shengcai Paper Packaging — we will provide an exclusive material plan according to your product characteristics and budget, making your gift boxes not only high-end but also cost-controllable.

As a packaging company, I’ve seen how small details can […]

The factors that influence the quality grade of packagi […]

When it comes to custom gift boxes, choosing the right […]

As Foshan Shengcai Paper Packaging with more than twent […]