In the gift consumption scenario, packaging is no longer just a “box for holding things” — consumers expect it to be visually appealing and, more importantly, convenient, safe, and reusable. For custom paper gift box manufacturers, improving packaging practicality not only enhances consumer satisfaction but also indirectly boosts brand reputation and repurchase rates. Below are core optimization directions combined with real scenarios, plus common Q&A, to make the ideas clearer.

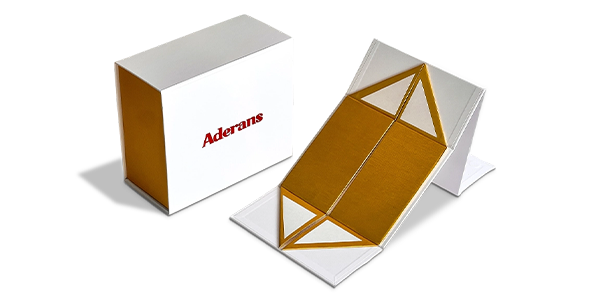

Structure is the foundation of packaging practicality, and it must fit the usage scenario. For example, during holiday gifting, consumers may need to open and close the gift box repeatedly. Adopting magnetic, buckle, or pull-out designs is more convenient for reuse than traditional adhesive seals. For gifts that need to be stacked (such as gift boxes of snacks or skincare sets), designing a trapezoidal box body or reinforced bottom structure can improve load-bearing capacity and avoid deformation during transportation or storage.

Choosing the right materials doubles practicality. custom paper gift box manufacturers can flexibly match materials according to product characteristics. Here’s a reference for practical material choices:

| Material Type | Core Advantages | Application Scenarios | Environmental Performance |

|---|---|---|---|

| High-strength Kraft Paper | Strong toughness, high load-bearing | Alcohol, electronic products, heavy gifts | 100% recyclable |

| Recycled White Cardboard | Good texture, moderate cost | Cosmetics, small accessories, stationery gift boxes | Recycled raw materials, low pollution |

| Honeycomb Composite Cardboard | Excellent cushioning, lightweight | Glassware, ceramics, fragile gifts | Degradable, high recycling rate |

| Waterproof Coated Paper | Moisture and stain resistant | Food, outdoor scenario gifts | Environmentally friendly coating options |

Reasonable internal layout prevents product damage from shaking and improves space utilization. For example, design dedicated slots for small items like lipsticks and perfumes, and foldable liners for soft gifts like clothing and scarves. Meanwhile, reserve 5%-10% buffer space to cope with slight vibrations during transportation and reduce damage rates.

Nowadays, 78% of consumers are more willing to choose environmentally friendly packaging. custom paper gift box manufacturers can start from two aspects: first, prioritize recyclable and biodegradable materials and reduce the use of plastic accessories; second, simplify the packaging structure, adopt glue-free or easy-to-disassemble designs to facilitate consumers’ classification and recycling.

To maintain practicality advantages in the long term, continuous optimization is essential. Here are 3 efficient feedback collection channels:

Q: Will improving packaging practicality increase production costs?A: Not necessarily. For example, choosing recycled paper materials costs about the same as ordinary paper but meets environmental needs. When optimizing structural design, adopting modular production can improve production efficiency and offset additional design costs. The key is to find a balance between “practical needs” and “cost control.”

Q: Can practical packaging and aesthetics be balanced?A: Absolutely. For example, magnetic gift boxes can be combined with bronzing and embossing processes, and recycled paper gift boxes can enhance texture through printed patterns. Practical functions will not affect aesthetics; instead, they can make the packaging more memorable.

For custom paper gift box manufacturers, the practicality of packaging stems from in-depth insight into consumer needs — from structure and materials to detail design, every link should focus on “ease of use, durability, and environmental protection” to make packaging truly serve products and consumers. Through continuous optimization and innovation, manufacturers can not only enhance product competitiveness but also establish differentiated advantages in the market.

1. First, Break the Misunderstanding: Grey Board ≠ Low- […]

Many friends who make products ask me: “I want to do gi […]

1. Key Points for Audience Targeting of Cosmetic Custom […]

Walking down a busy street, have you ever glanced twice […]