In the global packaging market, Custom Rigid Boxes have become a go-to choice for brands looking to elevate product presentation—whether for luxury goods, premium gifts, or high-end electronics. But anyone who’s sought quotes for these boxes knows the pricing can vary wildly: a 500-piece order might cost $3.5 per unit for one supplier, while another quotes $5.2. Why the huge gap? As someone who’s worked with packaging manufacturers and brand clients for years, I’ve noticed that most price confusion stems from a lack of transparency around cost drivers. Let’s break down the key factors that truly shape the price of Custom Rigid Boxes, with real-world insights to help you make smarter purchasing decisions.

The cardboard used for Custom Rigid Boxes is far from one-size-fits-all, and its quality directly impacts both durability and price. Most manufacturers use grayboard as the core, but the thickness (measured in pt) and surface paper grade make all the difference.

| Material Type | Cost Level | Key Use Case | 2025 Market Price Range (Per Sheet) |

|---|---|---|---|

| 800pt Grayboard + Standard Art Paper | Medium | Mid-range gifts, electronics | $0.8 – $1.2 |

| 1000pt Grayboard + Special Textured Paper | High | Luxury cosmetics, premium wine | $1.5 – $2.3 |

| Recycled 900pt Grayboard + Eco-Friendly Coating | Medium-Low | Sustainable brands, apparel | $0.6 – $0.95 |

Say you’re a skincare brand opting for textured paper—you’re not just paying for the material itself, but also the production yield (textured paper is trickier to cut, leading to 5-8% more waste). In most cases, upgrading from standard to special paper adds 20-30% to the unit cost, but it’s often worth it for the tactile feel that resonates with luxury buyers.

Custom Rigid Boxes stand out because of their refined craftsmanship, but each extra process tacks on time and labor costs. Let’s talk about common add-ons: hot stamping (gold or silver) requires custom dies, which cost $50-$150 upfront—though this fee gets amortized for large orders. UV printing, which gives logos a glossy, scratch-resistant finish, adds $0.3-$0.5 per box depending on the design size.

Magnetic closures are another popular upgrade—they make unboxing smoother, but assembling the magnets by hand increases labor time by 15-20%. I once worked with a fashion brand that skipped magnetic closures for a 10,000-piece order and saved 18% on total costs, without compromising brand perception. It all comes down to prioritizing which crafts align with your product’s value proposition.

Bulk purchasing is where the biggest cost savings lie for Custom Rigid Boxes. For example, a 1000-piece order of 8x6x4 inch boxes might cost $4.2 per unit, but bumping that to 5000 pieces drops the price to $2.9—thanks to reduced setup time, material bulk discounts, and lower per-unit labor costs.

Size matters too, but not in the way you might think. A box that’s too large for your product wastes material, but an overly small box requires more precision cutting (and higher reject rates). Odd-shaped Custom Rigid Boxes (like hexagonal or cylindrical) can cost 30-40% more than rectangular ones, as they require custom molds and slower production lines.

More and more brands are asking for eco-friendly Custom Rigid Boxes, but sustainable materials and processes do come with a slight premium. Recycled grayboard costs 10-15% less than virgin material, but adding compostable coatings or FSC-certified paper can increase costs by 8-12%.

The good news? This premium is shrinking as demand grows—2025 data shows that eco-friendly packaging materials are now used in 45% of B2B orders, up from 32% in 2023. Many manufacturers, including those specializing in custom packaging solutions, offer flexible options to balance sustainability and budget.

Q: Will adding custom inserts (like foam or velvet) to Custom Rigid Boxes significantly increase costs?

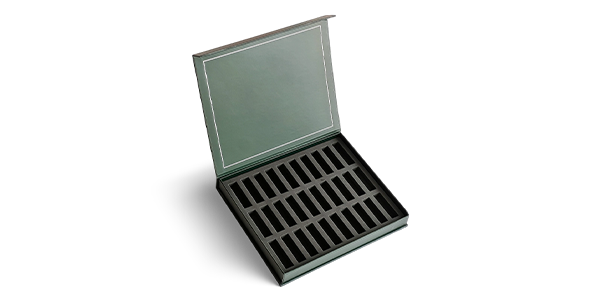

A: It depends on the material—basic foam inserts add $0.2-$0.4 per box, while velvet or custom-molded inserts can add $1-$1.8. For fragile products (like jewelry or glassware), the extra cost often prevents damage during shipping, saving money long-term.

Q: Is there a minimum order quantity (MOQ) for Custom Rigid Boxes, and how does it affect pricing?

A: Most factories have an MOQ of 500 pieces for standard designs—below that, setup costs make unit prices skyrocket. For small-batch orders (200-500 pieces), look for manufacturers that offer “economic runs” (using existing dies or simpler crafts) to keep costs in check.

Q: How much does color printing impact the price of eco-friendly custom rigid boxes?

A: Each additional color adds $0.1-$0.2 per box. Opting for 1-2 accent colors instead of full-color printing can save 10-15%, while still keeping the design eye-catching.

When it comes to Custom Rigid Boxes, pricing transparency isn’t just about knowing the numbers—it’s about understanding how each choice aligns with your brand goals and budget. Whether you’re a startup looking for cost-effective packaging or a luxury brand prioritizing premium details, the key is to work with a manufacturer that breaks down costs clearly, without hidden fees. After all, the best packaging investment is one that delivers value without breaking the bank.

Did you know? A 2026 consumer behavior survey found tha […]

1. Why Handbag Printing Matters for Gift Packaging Bran […]

Many clothing brands struggle with retail clothing pape […]

When it comes to custom gift boxes, choosing the right […]